-

P320 Testing - Introduction

graygunsBruce Gray, president of Grayguns, discusses the upcoming series of videos related to our internal testing of the SIG Sauer P320 pistol.1.14K views 2 comments

graygunsBruce Gray, president of Grayguns, discusses the upcoming series of videos related to our internal testing of the SIG Sauer P320 pistol.1.14K views 2 comments -

SIG Sauer P320 Video - Five Steps Required for the Pistol to Fire

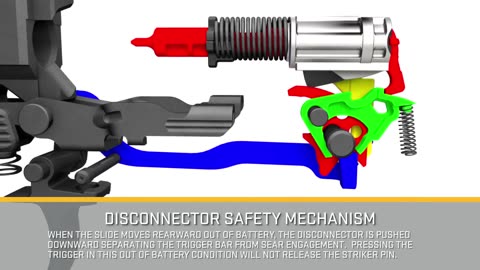

GGraygunsThis video is also posted on the SIG Sauer website. Five steps are required to fire a P320. 1 - The Trigger is pressed to the rear, moving the Trigger Bar forward. 2 - The Safety Lever rotates upward. 3 - The Striker Safety Lock rotates upward. 4 - The Sear rotates downward. 5 - The Striker Pin is released.371 views -

P320 Testing - FBI Report & Striker Safety Lock Test

GGraygunsIn this video, Bruce Gray discusses select sections of the FBI Ballistic Research Facilities SIG Sauer M18 Evaluation Report for the Michigan State Police.448 views 2 comments -

P320 Testing - Striker Safety Lock Spring

GGraygunsAs we continue testing related to P320 uncommanded discharge claims, this video covers the striker lock and the striker safety lock spring. Could the spring become dislodged or installed incorrectly in such a way that causes the striker lock to fail or be disabled? Would this result in the pistol firing if the striker lock were able to depart the sear? After measuring all parts, including the generational changes, we determined that the striker lock spring cannot get between the striker housing and the striker lock and disable it. We could not find a way to assemble it with the spring out of place, and once in place, there was no place for it to go. If you test the P320 with holes in the slide to visualize and inspect the spring while it is in place, the spring becomes unsupported. If that is the case, the spring can certainly get out of position.369 views -

P320 Testing - Safety Lever Spring

GGraygunsIn this video, we review the evolution of SIG's P320s safety lever spring and the eventual removal of that spring as a result of the August 2017 voluntary upgrade program.286 views -

P320 Testing - Mangled Sear & Trigger Bar Springs

GGraygunsToday we’re examining the sear and trigger bar springs. Some have suggested that crossed sear springs, or a trigger bar spring that’s been mangled during installation or otherwise damaged, could create a mechanical condition in which a P320 might fire without the trigger being pulled. To test this, we intentionally installed a damaged but still functional trigger bar spring, crossed the sear springs, and began our evaluation. Our testing included mounting the pistol to a sawzall and running the tool, as well as performing a significant number of five-foot drops onto concrete. The results were clear: bent or improperly installed sear and trigger bar springs can affect trigger pull feel and reset behavior, but they do not create a mechanical condition that allows the pistol to fire without a trigger pull.300 views -

P320 Testing - Malformed & Worn Firing Mechanism Parts

GGraygunsIn this episode, we'll review the theory related to heavily worn or malformed fire control parts causing an uncommanded discharge of the pistol. If you have a heavily worn sear, striker foot, or parts that are malformed from the factory could they cause an issue? Could the combination of these worn or malformed parts result in an uncommanded discharge? For our testing, we used a used sear from a pistol with more than 40,000 rounds through it, plus an untold number dry fire repetitions. We also replicated wear and a factory defect of the striker foot. We also tested with a very warped trigger bar spring, and used only one sear spring for this testing period. We completed drop testing on concrete and about two hours in a vibrating tumbler. The pistol did not fail and the sear and striker foot held in place.374 views 1 comment -

P320 Testing - Striker Safety Lock Deformation, Misalignment, Jarring & Fouling

GGraygunsAt this point, one of our primary test pistols has been dropped more than 200 times and subjected to extensive additional testing. Throughout this process, we have not been able to create any mechanical condition that would allow the pistol to fire without a trigger pull. Today, we continued our evaluation by focusing on the striker safety lock. The question: Could the striker safety lock be bent or misaligned in a way that allows the striker to bypass it? To explore this, we sandblasted the components and intentionally bent the striker safety lock. After reassembling the striker without the striker lock spring, we jarred, struck, and manipulated the striker to see if we could force the safety lock out of position. Even with only the striker spring applying tension, the safety lock remained engaged. Next, we assembled the pistol without the striker safety lock spring and subjected it to additional impact and movement. Again, the striker safety lock did not disengage. Finally, we introduced debris into the fire-control unit and placed the pistol in a vibrating tumbler. The primed case did not ignite, and the striker safety lock remained fully engaged. In short, Grayguns could not produce any mechanical condition that would allow the pistol to fire without a trigger pull. The results consistently show no unintended firing events, even under deliberately compromised component conditions and aggressive testing scenarios.424 views -

P320 Testing - Tolerance Stacking & The Thousand Slices of Swiss Cheese

GGraygunsWe examined the claim that the conditions required to create a mechanical situation in which a pistol could fire without a trigger pull are so complex that they cannot be intentionally reproduced. Some suggest this explains why no one has ever demonstrated a repeatable, real-world scenario in which a P320 fires without the trigger being pulled. To put that theory to the test, we took one of our dedicated test pistols and intentionally introduced a wide range of severe mechanical issues, including: - Bent springs - Bent striker lock - Loose striker housing - Loose striker diameter and foot fit - Chiseled striker foot - Crushed reset spring - Extremely loose slide-to-FCU fit - Roughened surface finishes on parts - No striker lock spring - Offset housing pin - Worn sear - Crossed sear springs - Dead sear springs - Inverted striker lock spring - Bent takedown safety lever interference - Grit and fouling in the fire control unit - Loose sear housing - Undersized pins With all of these faults intentionally incorporated, the pistol was subjected to repeated drop testing and extreme vibration. Despite the combination of compromised components and aggressive testing, Grayguns could not produce any mechanical condition that allowed the pistol to fire without a trigger pull. The results consistently showed no unintended firing events under any of the imposed scenarios.675 views 6 comments