Premium Only Content

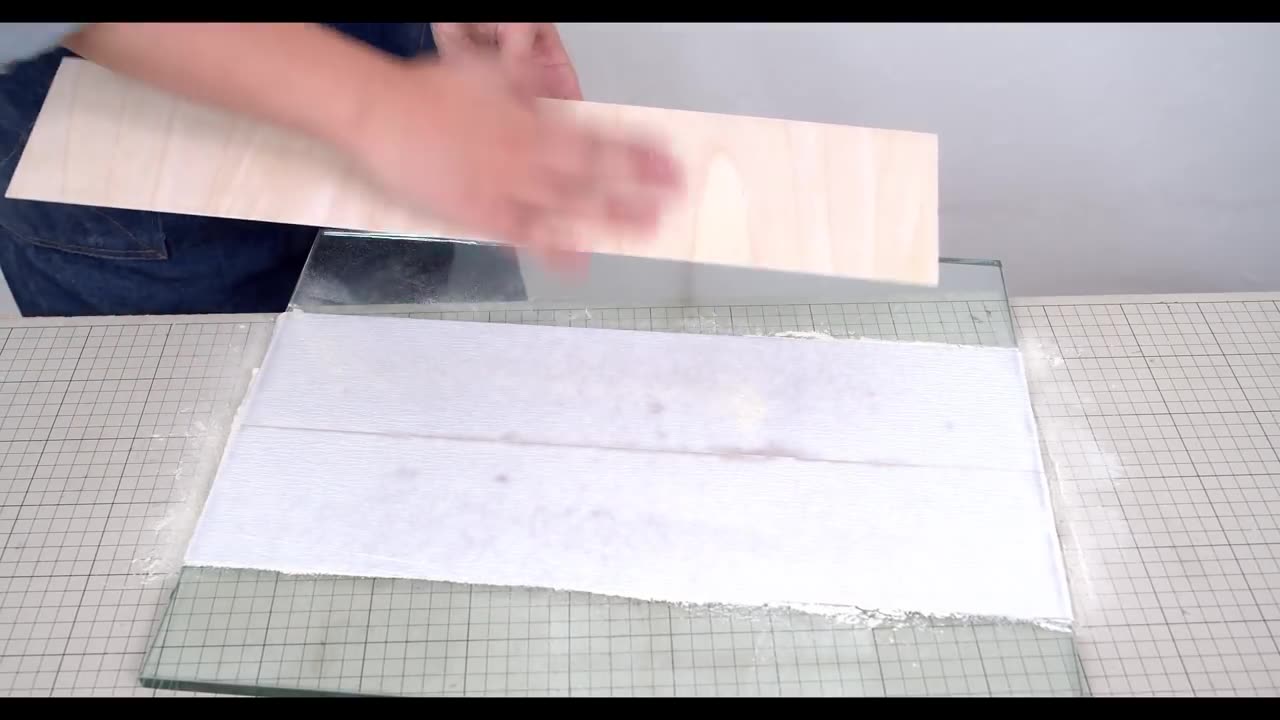

Amazing Benchtop Jointer - How to Make a Jointer - Rig System Part.3

Creating an amazing benchtop jointer as Part 3 of a rig system project can significantly enhance the precision and quality of your woodworking tasks. Here's how you can structure this segment:

Introduction:

Introduce Part 3 of the rig system project, focusing on the construction of a benchtop jointer.

Highlight the benefits of having a homemade jointer, including cost-effectiveness and customization options.

Materials Needed:

List the materials required for this part of the project, such as:

Plywood or MDF for the base and frame

Aluminum or steel rails for the jointer bed

Electric motor or hand-crank mechanism

Cutting blades or cutter heads

Screws, bolts, and nuts

Safety equipment (goggles, gloves, etc.)

Tools Needed:

Provide a list of tools necessary for the construction process, including:

Circular saw or jigsaw for cutting materials

Drill and drill bits for making holes

Screwdriver or wrench for assembly

Measuring tape and pencil for marking

Construction Steps:

Design and Layout:

Discuss the design considerations for the benchtop jointer, including size, bed length, and fence design.

Use sketches or diagrams to illustrate the layout and dimensions of the components.

Building the Base and Frame:

Cut the plywood or MDF according to the design specifications to create the base and frame of the jointer.

Assemble the base and frame using screws or bolts, ensuring stability and rigidity.

Installing the Jointer Bed:

Attach aluminum or steel rails to the base to serve as the jointer bed.

Ensure the rails are aligned parallel to each other and spaced appropriately for the cutting mechanism.

Mounting the Cutting Mechanism:

Install the electric motor or hand-crank mechanism to drive the cutting blades or cutter heads.

Position the cutting mechanism on the jointer bed, ensuring smooth and precise movement.

Adding Safety Features:

Incorporate safety features such as blade guards or emergency stop switches to prevent accidents during operation.

Safety Precautions:

Remind viewers to exercise caution when working with power tools and sharp objects.

Emphasize the importance of wearing appropriate safety gear, such as goggles and gloves, to prevent accidents or injuries.

Conclusion:

Summarize the key steps covered in Part 3 of the rig system project.

Encourage viewers to experiment with their own homemade jointers and share their experiences with the community.

By providing clear instructions and demonstrations, you can create an informative and engaging Part 3 video for your amazing benchtop jointer rig system project, inspiring viewers to explore new possibilities in their woodworking endeavors.

-

14:57

14:57

Upper Echelon Gamers

9 hours ago $0.07 earnedNot Even The Tech Bros Want Their Own Tech

184 -

9:06

9:06

Adam Does Movies

13 hours ago $0.08 earnedKeeper - Movie Review

206 -

1:22:24

1:22:24

Mike Mac - Say Something

13 hours agoSay Something Beyond W/MikeMac: JARED SILVER - Ep.16

361 -

8:29

8:29

Freedom Frontline

13 hours agoEric Schmitt Plays One Charlie Kirk Clip And Democrats Panic Instantly

2905 -

LIVE

LIVE

BEK TV

2 days agoTrent Loos in the Morning - 12/01/2025

228 watching -

LIVE

LIVE

The Bubba Army

4 days agoTRUMP IGNITES NEW CONFLICT with VENEZUELA - Bubba the Love Sponge® Show | 12/01/25

2,289 watching -

11:26

11:26

MattMorseTV

1 day ago $26.75 earnedLindsey Graham is in HOT WATER.

36.1K141 -

LIVE

LIVE

Pickleball Now

5 hours agoLIVE: IPBL 2025 Day 1 | India’s First Official Pickleball League Starts with Top Teams in Action

284 watching -

12:52

12:52

Nikko Ortiz

15 hours agoWorst Thanksgiving Dinner Of All Time...

89.1K15 -

12:56

12:56

MetatronHistory

1 day agoWhat is the actual difference between Vikings and Normans?

11.4K3