Premium Only Content

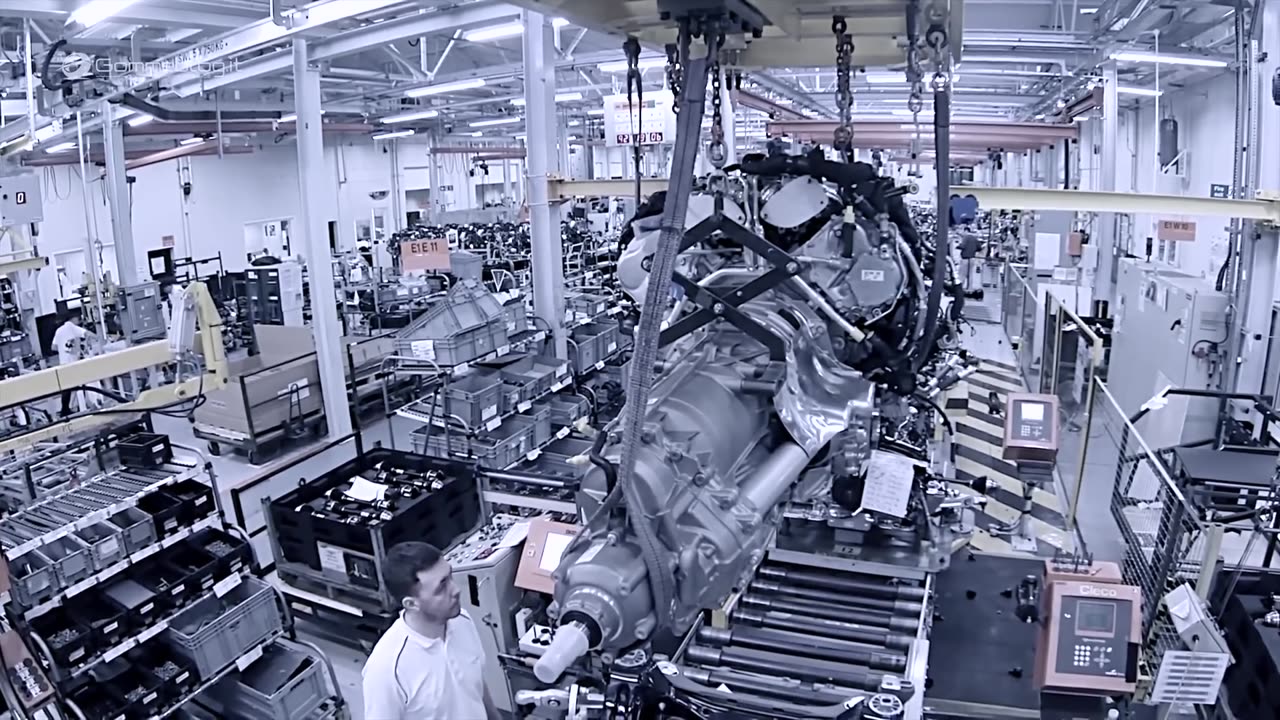

Engine Block Casting Production Car Factory Manufacturing

Engine block casting production is a critical step in the manufacturing of internal combustion engines, and it involves several intricate processes that are often referred to as "the secret process" in car factories due to the precision and complexity involved. One of the key techniques employed in this process is Computer Numerical Control (CNC) machining. Here's an overview of the secret process behind car factory CNC engine block casting production:

Pattern and Mold Preparation:

The process begins with the creation of a pattern, typically made of wood or resin, which is a replica of the engine block's shape. The pattern is used to create a mold, which is made from a heat-resistant material like sand mixed with a binder. This mold will determine the final shape of the engine block.

Casting Material:

Engine blocks are commonly made from cast iron or aluminum alloy. The choice of material depends on factors such as engine performance requirements, weight considerations, and cost.

Melting and Pouring:

The selected material is melted in a furnace at extremely high temperatures. Once molten, it is poured into the mold, which has been carefully prepared to ensure uniformity and precision.

Cooling and Solidification:

After pouring, the molten metal begins to cool and solidify within the mold. This phase is crucial for achieving the desired material properties and dimensional accuracy.

Shakeout and Cleaning:

Once the metal has cooled and solidified, the mold is shaken out, and the rough casting is removed. Any excess material or imperfections are cleaned and removed from the casting.

CNC Machining:

The heart of the secret process lies in the CNC machining phase. CNC machines are computer-controlled and highly precise tools that are used to shape and refine the engine block casting. This involves milling, drilling, boring, and honing to create the various passages for coolant, oil, and air, as well as to ensure the engine block's precise dimensions.

Quality Control:

Throughout the CNC machining process, rigorous quality control checks are performed to verify the engine block's dimensions, surface finish, and other critical specifications. Any deviations are corrected to meet the manufacturer's strict standards.

Surface Treatments:

Depending on the engine's design and requirements, additional surface treatments such as shot blasting, surface grinding, and chemical coatings may be applied to improve durability, heat dissipation, and overall performance.

Assembly Compatibility:

Engine blocks are designed to be compatible with other engine components, such as cylinder heads, crankshafts, and pistons. Precise machining ensures that these components can be assembled together seamlessly.

-

LIVE

LIVE

Lofi Girl

2 years agoSynthwave Radio 🌌 - beats to chill/game to

200 watching -

2:17:05

2:17:05

FreshandFit

4 hours agoFrom SMALLVILLE to AB'SVILLE w/ Sam Jones III

118K6 -

3:05:45

3:05:45

Price of Reason

11 hours agoTrump's UN Takedown! BACKLASH Over Disney's Jimmy Kimmel Return! Tulsa King Season 3 Premiere Review

124K16 -

3:03:12

3:03:12

Badlands Media

13 hours agoDEFCON ZERQ Ep. 010: Government Overreach and the Battle for Freedom

169K56 -

9:46

9:46

Levi

1 day agoWhy XRP's Bull Run Will Be 10x Bigger Than The Last One - Raoul Pal

7.92K1 -

20:13

20:13

Paul Barron Network

26 days ago $0.85 earnedXRP Vault Yields Coming in September!?🔥Flare CEO INTERVIEW

9.09K -

3:00:12

3:00:12

TimcastIRL

7 hours agoJimmy Kimmel Show IN CHAOS Before Return, Affiliates REFUSE, Staff Says THEYLL QUIT

360K107 -

2:49:26

2:49:26

Laura Loomer

8 hours agoEP145: Trump Makes BOMBSHELL Autism Announcement

51.9K19 -

6:14:04

6:14:04

SpartakusLIVE

9 hours agoEXPLOSIVE $400+ 2v2 Tuesday has viewers GLUED to the screen

63.3K2 -

3:19:06

3:19:06

GrimmHollywood

8 hours ago🔴LIVE • GRIMM'S TUESDAY FRIGHT NIGHT • STARRING GRIMM HOLLYWOOD • NO, I'M NOT HUMAN PART 1 •

45.8K2