Premium Only Content

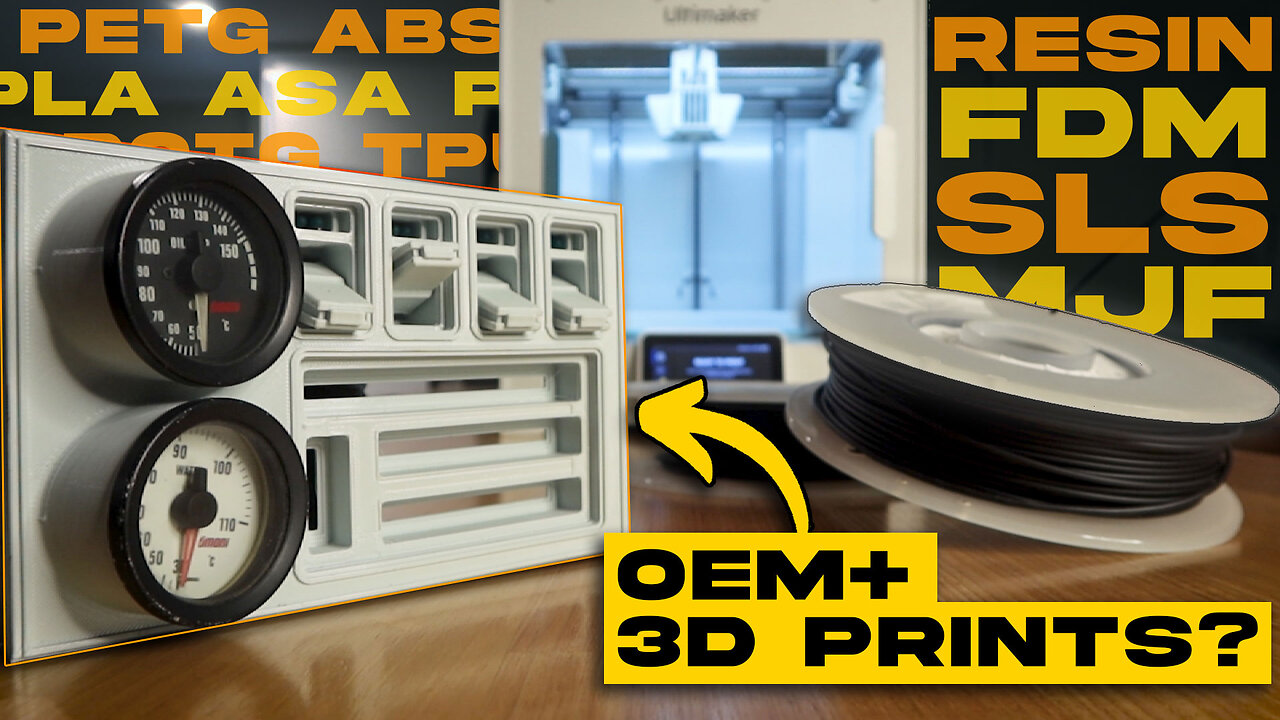

3D Printed Custom Dash | Best Materials for Car Parts (OEM+ Build)

We're back! In this episode, we dive deep into the process of choosing the right materials for a custom 3D printed OEM+ dashboard designed for my classic Toyota Corolla KE25 restoration project.

I break down the key material properties that matter when printing functional car interior parts — from PLA to PETG, ASA and carbon-reinforced filaments.

Whether you're restoring a project car, running a 3D printing business, or just want to learn about real-world engineering applications, this video covers:

✅ Best filament for car parts (PLA, PETG, ASA, Carbon-Fiber)

✅ OEM+ dash design and CAD modelling walkthrough

✅ 3D printing interior parts that actually last

✅ My top tips for functional 3D printed car mods

I’ll also walk you through the design process, show behind-the-scenes CAD modelling, and give you a preview of upcoming STL downloads, including a custom switch panel and interior mods. In the last video we covered a fair bit of 3D modeling for 3D printing and now it's time to have a look at the best filament for car parts (or resin?).

🔧 Covered in this video:

- What’s the *best filament for 3D printed car interior parts*?

- Is PETG strong enough for cars?

- OEM+ dashboard mods for classic Toyotas

- 3D printing vs injection molding for small batch production

- How to design printable car parts that won’t warp or melt

- Engineering breakdown of real-world print performance

Considering I've always got a few automotive projects on the go (junkyard car builds?) we're going to also cover a bit of the car restoration projects as we prep both the KE70 for its upcoming “unnecessary Toyota corolla turbo kit”™ and the KE25 corolla coupe for it's roadworthy certificate.

3D printing metal car parts is something I have planned for a couple of future projects, but there is still a lot that can be achieved with regular old plastic/polymer 3D printing.

3D printing for automotive use can also be a bit of a contentious topic as everyone seems to have an opinion on it, but as you'll see in this video I've covered quite a few different materials and scenarios including examples of how I've tested and used them.

3D printing is without a doubt a pretty substantial manufacturing innovation, and has been a game-changer, particularly for prototyping products and automotive projects that might be later CNC machined or similiar - however, there are still plenty of end-use cases for 3D printing and I'll talk about some of them in this video.

DIY car repair is another thing that 3D printing is perfect for, and although I don't cover it in this video - I will continue to talk more about materials and how I apply 3D printing to both my 3D printing car parts business and other car restoration projects. Another particularly handy material is the flexible TPU filament, but we'll cover that very soon.

As you'll see I've also made a subscription service on my website (www.fatlipcollective.com.au) and even if you sign up for a free account I have two 3D models available for you to download and print yourself at home, or incorporate into your own CAD projects. 3D printing engineering workshop storage containers etc. is something I have covered in other videos as well and I think I will try to make quite a few of these files available too, but as always I'm happy to hear any requests or suggestions that you may have!

As always, thanks for watching - I really appreciate it ✌.

_____________________________________________________________________

www.fatlipcollective.com.au

Socials: @Fat Lip Collective

Music by: Marcus: @frshngtz

_____________________________________________________________________

#3DPrinting #CarRestoration #EngineeringSimplified #KE25 #KE70 #AutomotiveMods #FatlipCollective

-

1:14:37

1:14:37

Flyover Conservatives

1 day agoHow to Win 2026 Before It Starts — Clay Clark’s Goal-Setting Blueprint | FOC Show

35.5K1 -

12:52

12:52

The Kevin Trudeau Show Limitless

2 days agoBeyond Good And Bad: The Hidden Reality Code

77.8K21 -

1:03:11

1:03:11

BonginoReport

10 hours agoBrown U Security Failures EXPOSED - Nightly Scroll w/ Hayley Caronia (Ep.201)

155K47 -

51:09

51:09

Patriots With Grit

6 hours agoWill A.I. Replace Doctors? | Dr. Stella Immanuel MD

24.2K4 -

4:10:32

4:10:32

Nerdrotic

12 hours ago $15.34 earnedHollywood's DOOMSDAY! WB FIRESALE! - Friday Night Tights 385 w Zachary Levi

84.1K19 -

12:25:53

12:25:53

LFA TV

23 hours agoLIVE & BREAKING NEWS! | FRIDAY 12/19/25

204K31 -

1:08:59

1:08:59

Edge of Wonder

9 hours agoNASA’s Intergalactic Spacecraft, Real Dwarves Spotted & Research Roundup

28.7K7 -

1:21:27

1:21:27

Kim Iversen

12 hours agoPutin Says Russia is Ready for WAR With Europe

48.5K103 -

1:24:41

1:24:41

The Daily Signal

10 hours ago $7.32 earned🚨BOMBSHELL: 315,000+ Illegal Ballots in Georgia, Terrorists Released, Rubio Slashes Foreign Aid

36.5K13 -

1:53:45

1:53:45

The Mike Schwartz Show

12 hours agoTHE MIKE SCHWARTZ SHOW Evening Edition 12-19-2025

25.7K4